The so-called non-oil means less fuel without refueling, the goal of our research is to ensure that bearing this condition also showed a good performance and extend its life as much as possible. Self-lubricating bearings basic principle is that the solid lubricant in the initial operational phase of the bearing surface due to mutual friction asked to form a transfer film and covered with a wear member to the final formation of the solid lubricant film in order to achieve the purpose of self-lubricating, it cut off direct contact between the workpiece and thus well protected against wear member and workpiece extending bearing life.

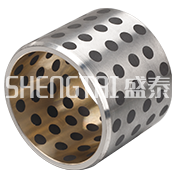

JDB high-strength copper alloy as base material, according to the use conditions by a certain percentage of its working surface machined hole and fill one solid lubricant. High-strength copper alloy provides a high load carrying capacity and the solid lubricant can be formed of a low friction. Under dry conditions we have designed a layer of film on pre-lubricated bearing surface ensures the shortest possible time will be transferred to the solid lubricant on the coupling member and form a valid solid lubricant film.

Modern design for today's self-lubricating bearing material is undergoing tremendous demand. Even in the severe operating environment and maximum extreme load conditions also require maintenance. As the cost of the increasing demand, business equipment and plant operation reliability requirements are also increasing. Metal self-lubricating bearings to meet the long-term maintenance-free and under the conditions of use of self-lubricating, thus making the design of reliable long-term self-lubricating system possible. Metal type self-lubricating bearing material can be widely used in high-load low speed rotation conditions, swivel and linear reciprocating motion, but also for conventional lubrication can not be achieved or prohibit the use of the occasion, or in special conditions such as dust, shock load or irradiation conditions require long-term and stable use.

| Model / corresponding trademark | JDB-1 | JDB-2 | JDB-3 | JDB-4 | JDB-2 | ||

|---|---|---|---|---|---|---|---|

| JDB-2 | JDB-22 | JDB-23 | |||||

| International brands GB1776-87 | ZCuZn25 Al6Fe3Mn3 |

ZCuSn6Zn6Pb3 | ZCuAl10Fe3 | ZCuSu10P1 | Steel+ ZCuSn6Zn6Pb3 | HT250 | GCr15 |

| International ISO1338 | GCuZn25 Al6Fe3Mn3 |

GCuSn6Zn6Pb3 | GCuAl10Fe3 | - | Steel + CuSn6Zn6Pb3 Fe3Ni5 |

- | B1 |

| Germany DIN | G-CuZn25 Al5 |

GB-CuSn5Zn5Pb5 | GB-CuAl10Ni | GB-CuSn10 | Steel + CuSn6Zn6Pb3Ni | - | 100Cr6 |

| Japan JIS | HBsC4 | BC6 | AIBC3 | BC3 | BC6 | FC250 | SUJ2 |

| American ASTM/UNS | C86300 | C83600 | C95500 | C90500 | C83600 | Class40 | 52100 |

| British Standard(BS) | HTB2 | LG2 | AB1 | PB4 | LG2 | - | - |

| Solid lubricant | ||

|---|---|---|

| Solid lubricant | Characteristic | Typical use |

| SL1 High purity graphite + additive |

Good wear resistance and chemical stability, temperature<400℃ | Used in general machinery, used in the air |

| SL4 PTFE + additive |

Low friction coefficient and excellent moist resistance, temperature <300 ℃ | Applied to water, sea water lubrication, such as ships, hydraulic arc door, turbine, pharmaceutical machinery, and other beverages. |

1.No oil supply device, hole injection, fuel tank processing

Cost of oil installations, processing fees, saving assembly fees, extra costs and time, can significantly reduce manufacturing costs.

2.Lower operating costs

Significantly reduce the use of lubricants and equipment maintenance costs, while also eliminating the risk caused due to insufficient supply.

3.Shorten design time

Non-oil can make the design and structure greatly simplified, reducing costs, saving design time. In addition, the use of self-lubricating bearings can also improve the mechanical properties, extend life and improve reliability, achieve significant results.

4.Oil recovery and environmental protection

No waste oil recycling, are environmentally friendly.

JDB(500#SP) Self-lubricating bearings as machinery parts and components industry, there is some use in a broad sense. In order to make the mechanical drive is operating normally, a lot of effort. The bearing is divided into Rolling and plain bearings. General sliding bearings under high load movement, foreign matter, the temperature condition, fuel, maintenance, etc. imperfect, can cause nap. Under severe conditions such as general sliding bearings can not be used, solid metal mosaic self-lubricating bearings wear resistance, galling resistance, the bearing play its due performance, to achieve the role of mechanical performance and maintenance-free maintenance.

1. Flexible design, simple and convenient, using a wide range;

Oil supply system in the mechanical design is a lot of work, time-consuming device, the use of solid self-lubricating bearings need not be considered in the design of fuel means saving fuel plant equipment, and can for a variety of special occasions, the solid self-lubricating bearings designed into a variety of shapes to meet the needs of a variety of special occasions, the use of solid self-lubricating bearings, can significantly reduce the mechanical maintenance, fuel and other expenses.

2. No oil can be used;

Since the coefficient of linear expansion of solid self lubricant is greater than the metal substrate, so when solid self-lubricating bearings start running, the film will be transferred to the upper grinding member achieved self-lubricating, so solid self-lubricating bearings can be used in difficult to refuel and can not refuel or fat place, even in the case of low speed, high load, but also can play a good lubrication.

3. Low cost;

Traditional mechanical design, operating within a certain time, to regular refueling and maintenance, check the fuel gauge, oil installations is smooth, due to regularly refuel the body itself and cause pollution of the surrounding environment, resulting in increase of the maintenance costs and achieve after self-lubricating, not only can make the environment clean, but also greatly reduces the cost of the use of lubricants.

4. The high-load, low-speed conditions, can play a superior performance;

Solid self-lubricating bearings are used centrifugal casting high-strength brass alloy as a matrix, play a role in carrying the load, graphite has good self-lubricating properties of specially formulated as a lubricant, play a role in self-lubricating, it combines them the respective merits, even under high load, low speed conditions, can play a superior performance.

5. The reciprocating motion, rocking motion, start-stop and frequent film formation difficult place to play excellent wear resistance;

Solid lubricants self-lubricating bearing arrangement principle is to ensure that all parts of the grinding member has a lubricant effect during operation of the thus arranged with the lubricant must be based on the direction of movement of the grinding member arranged to determine the position of the lubricant.

6. superior chemical resistance and corrosion resistance;

Solid self-lubricating bearing lubricant is specially formulated with graphite, PTFE, molybdenum disulfide and other wear-resistant material, which has a stable molecular structure, metal matrix can have different chemical resistance and corrosion resistance depending on the metal of selected, solid self-lubricating bearings and therefore has excellent chemical resistance and corrosion resistance.

7. The cost of the product more competitive, compared with similar products, long working life, required little maintenance, replacement replacement cycle is long, a good performance.

JDB-1 Solid mosaic bearing, at high force brass substrate. Mosaic graphite or MoS2…

READ MORE >>

JDB-2 is made of bronze CuSn6Zn6Pb3 with graphite evenly embedded in it. It can…

READ MORE >>

JDB-3 is made of two kinds of material, steel back sintered…

READ MORE >>

JDB-4 is made of casting iron HT250 and embedded with solid lubricant. It is a typical…

READ MORE >>

JDB-5 Steel base mosaic bearing, strengthening products, has a high compression performance…

READ MORE >>

Shengtai perennial production of various types of non-standard products, in order to meet the needs of customers to use.

Home| About us| Products| Size| Design| Download| Applications| News| Contact us